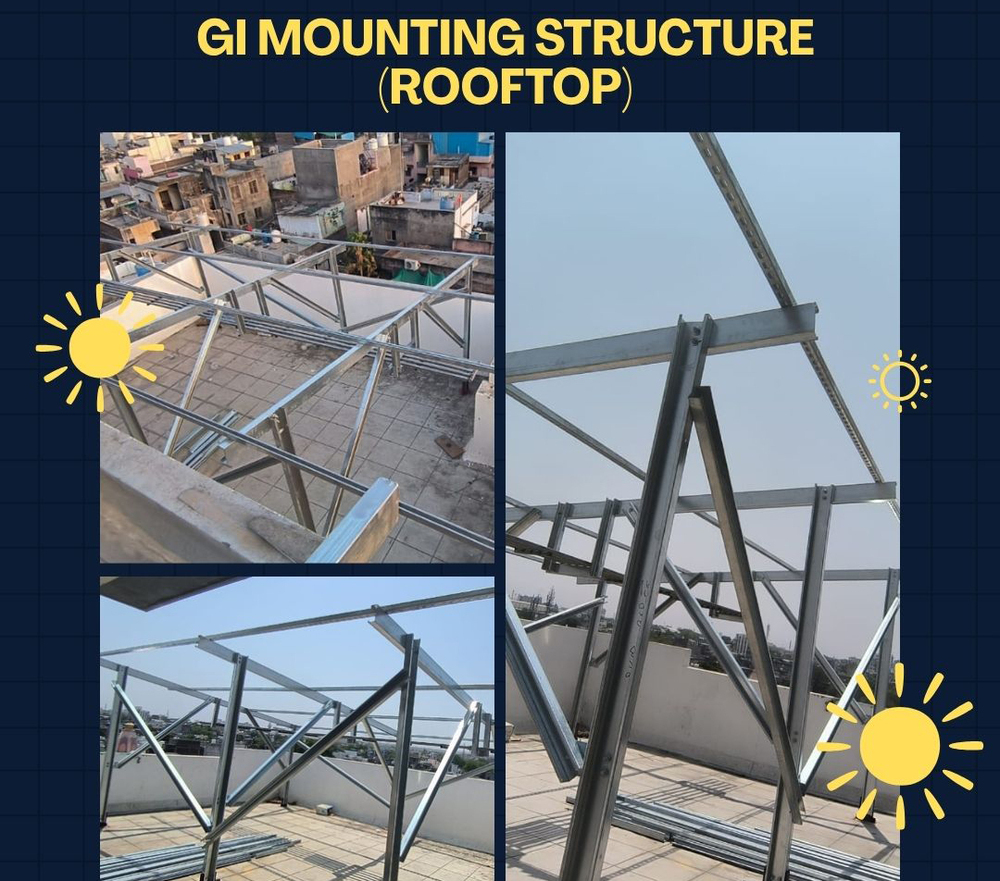

About GI Mounting Rooftop Structure

Description:

GI rooftop mounting structures provide a strong, rust-resistant base for solar panels. Built from hot-dip galvanized steel, these frames handle extreme temperatures, rain, and high wind loads without bending or corroding. They allow precise panel alignment and maintain correct tilt angles for maximum power generation.

Suitable for both RCC and metal roofs, the structure includes pre-engineered rails, supports, and SS hardware for quick installation. Ideal for residential, commercial, and industrial rooftops where long-term durability and structural integrity are non-negotiable.

Product Specifications:

- Material: Hot-dip galvanized (HDG) mild steel

- Galvanization Thickness: 6080 microns (standard), 80120 microns (heavy-duty)

- Structure Type: Fixed-tilt (1030), customizable as per roof angle

- Mounting Base: RCC roof (ballast or anchor bolt) / Metal sheet roof compatible

Tube/Channel Size:

- C-channel: 41x41 mm / 41x21 mm

- Square/rectangular pipes: 40x40 mm, 50x50 mm (varies by load requirements)

- Fasteners: SS304 bolts and nuts

- Wind Load Capacity: Designed for 150180 km/hr (as per site condition)

- Corrosion Resistance: High, suitable for 25+ year outdoor life

- Compatibility: All framed solar modules (300W700W)

- Installation: Pre-drilled, easy assembly with minimal tools

- Warranty: 510 years (manufacturer dependent)"

Superior Material & ConstructionThe structure utilizes hot-dip galvanized mild steel, ensuring protection against rust and extending the lifespan of rooftop installations. The rectangular and square shapes provide structural integrity, while the plain style offers streamlined installation on various rooftop types. This makes the GI Mounting Rooftop Structure a reliable choice for diverse urban and industrial environments.

Versatile Rooftop ApplicationsSpecifically crafted for rooftop usage, the GI Mounting Structure is ideal for mounting solar panels and similar equipment. Its standard size options, such as 4040 mm and 5050 mm, accommodate a range of project specifications. It supports efficient energy solutions across both residential and commercial spaces, helping to maximize rooftop potential.

FAQs of GI Mounting Rooftop Structure:

Q: How is the GI Mounting Rooftop Structure installed on rooftops?

A: Installation involves securely anchoring the rectangular or square sections onto the rooftop surface, followed by mounting solar panels or other equipment as needed. The hot-dip galvanized finish ensures the structure remains stable and rust-resistant during outdoor exposure.

Q: What materials are used in making this rooftop structure?

A: This rooftop structure is made from hot-dip galvanized mild steel, which offers enhanced durability and superior resistance to corrosion, suitable for long-term outdoor use.

Q: When should the GI Mounting Rooftop Structure be used?

A: It should be used whenever robust support for rooftop solar panels or similar installations is needed, especially where reliability and longevity are crucial.

Q: Where can I purchase this rooftop mounting structure in India?

A: You can acquire this product from prominent distributors, exporters, manufacturers, suppliers, and traders throughout India who specialize in high-quality rooftop structures.

Q: What is the typical process for manufacturing the GI Mounting Rooftop Structure?

A: The process involves fabricating mild steel into rectangular or square profiles, followed by hot-dip galvanization to coat and protect against corrosion. The finished structure is then quality-tested before distribution.

Q: How is this structure beneficial for rooftop installations?

A: Its hot-dip galvanized coating guarantees longevity and minimal maintenance while providing strong support for equipment. These qualities ensure efficient, safe, and reliable rooftop installations, adding value to residential and commercial properties.

Q: What are the size options available for this rooftop structure?

A: The GI Mounting Rooftop Structure is available in standard sizes such as 4040 mm and 5050 mm, catering to various project requirements and load demands.